Advancing Technology with Boron Nitride Tubes: Properties, Applications, and Innovations

Introduction to Boron Nitride Tubes:

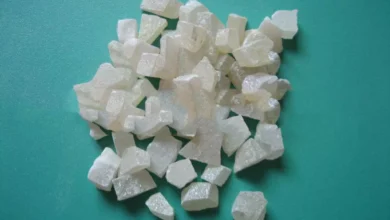

Boron Nitride Tubes represent a significant advancement in materials science, offering exceptional properties and versatility in various high-temperature and corrosive environments. This comprehensive article delves into the significance, properties, manufacturing processes, applications, benefits, and advancements associated with Boron Nitride Tube, highlighting their pivotal role in technological advancements across industries.

Understanding Boron Nitride Tubes:

Boron Nitride Tubes are advanced ceramic materials composed of boron and nitrogen atoms, arranged in a hexagonal lattice structure. They exhibit unique properties such as high thermal stability, excellent thermal conductivity, electrical insulation, chemical inertness, and lubricity, making them ideal for demanding applications in extreme environments.

Properties of Boron Nitride Tubes:

- High Thermal Stability: Boron Nitride Tubes can withstand high temperatures, up to 1800°C in inert atmospheres, and exhibit excellent thermal shock resistance, making them suitable for use in thermal management applications and high-temperature processes.

- Excellent Thermal Conductivity: These tubes possess high thermal conductivity, comparable to that of metals, allowing for efficient heat transfer and dissipation in thermal insulation, heat exchangers, and electronic cooling applications.

- Electrical Insulation: Boron Nitride Tubes exhibit electrical insulation properties, making them suitable for use as electrical insulators, dielectric components, and substrates in electronic and semiconductor devices.

- Chemical Inertness: They are chemically inert, resistant to most chemicals, acids, and alkalis, providing corrosion resistance and stability in harsh chemical environments.

- Lubricity: Boron Nitride Tubes have low friction coefficients and high lubricity, making them effective lubricants and coatings for reducing friction, wear, and adhesion in mechanical systems.

Manufacturing Processes for Boron Nitride Tubes:

- Hot Isostatic Pressing (HIP): Boron Nitride Tubes can be produced using HIP, where boron nitride powder is compacted at high pressures and temperatures to form dense, uniform tubes with controlled properties.

- Extrusion: Extrusion processes involve forcing boron nitride paste or powder through a die to produce tubes of desired dimensions and shapes, followed by sintering to achieve the final properties.

- Chemical Vapor Deposition (CVD): CVD techniques can be used to deposit boron nitride coatings or films onto substrates, including tubes, to enhance their surface properties or add functional layers.

- Injection Molding: Injection molding of boron nitride compounds can be employed to fabricate intricate tube geometries with enhanced mechanical properties and thermal conductivity.

Applications of Boron Nitride Tubes:

- Thermal Management: Boron Nitride Tubes are used in thermal management applications, such as heat sinks, heat exchangers, and thermal insulation, where they dissipate heat efficiently and maintain thermal stability.

- Electronics and Semiconductors: They find applications in electronics and semiconductor industries as electrical insulators, heat spreaders, substrates for electronic components, and crucibles for semiconductor manufacturing.

- Chemical Processing: Boron Nitride Tubes are utilized in chemical processing equipment, reactors, and crucibles due to their chemical inertness, corrosion resistance, and thermal stability in aggressive chemical environments.

- Mechanical Engineering: They are used in mechanical engineering applications, such as bearings, seals, bushings, and coatings, to reduce friction, wear, and adhesion in high-temperature and high-load conditions.

- Biomedical and Aerospace: Boron Nitride Tubes have applications in biomedical implants, aerospace components, and protective coatings due to their biocompatibility, thermal properties, and resistance to oxidation.

Benefits of Boron Nitride Tubes:

- High Temperature Resistance: Boron Nitride Tubes can withstand extreme temperatures without deformation or degradation, making them suitable for use in high-temperature applications.

- Thermal Conductivity: They offer high thermal conductivity, allowing for efficient heat transfer and dissipation, which is beneficial in thermal management and heat exchanger applications.

- Chemical Inertness: Boron Nitride Tubes are chemically inert and resistant to corrosion, making them durable and reliable in harsh chemical environments.

- Electrical Insulation: They provide excellent electrical insulation properties, preventing electrical conduction and breakdown in electronic and high-voltage applications.

- Lubricity: Boron Nitride Tubes exhibit low friction coefficients and high lubricity, reducing wear, friction, and adhesion in mechanical systems.

Advancements and Innovations in Boron Nitride Tubes:

- Nanostructured Boron Nitride Tubes: Research is ongoing to develop nanostructured boron nitride tubes with enhanced properties, such as improved thermal conductivity, mechanical strength, and surface functionality.

- Functional Coatings: Innovations focus on developing functional coatings and surface treatments for boron nitride tubes to tailor their properties for specific applications, such as anti-corrosion coatings, thermal barrier coatings, and bioactive coatings.

- Composite Materials: Boron Nitride Tubes are being incorporated into composite materials, such as boron nitride-reinforced polymers or ceramics, to create hybrid materials with combined properties for advanced applications.

- Additive Manufacturing: Additive manufacturing techniques, such as 3D printing, are being explored for fabricating boron nitride tubes with complex geometries and customized properties, offering new possibilities in design and functionality.

Conclusion:

Boron Nitride Tubes represent a remarkable advancement in materials science, offering a unique combination of properties that make them invaluable in various industries and applications. With their high thermal stability, thermal conductivity, electrical insulation, chemical inertness, and lubricity, boron nitride tubes continue to drive innovation, efficiency, and reliability in technologies related to thermal management, electronics, chemical processing, mechanical engineering, and aerospace. As research and development efforts continue to advance, the potential of boron nitride tubes in emerging applications and technologies is expected to grow, further cementing their role as essential materials for the future.